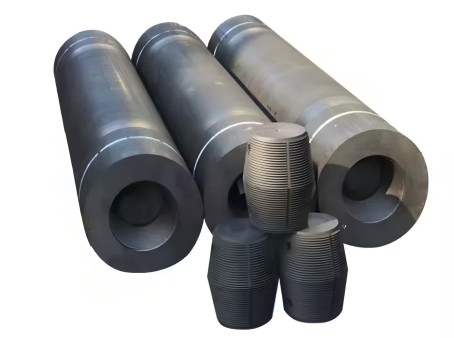

Graphite Electrode

◐Graphite electrodes are mainly used in electric arc furnace. They are presently the only products available that have the high levels of electrical conductivity and the capability of sustaining the extremely high levels of heat generated in EAF.

Product Details

1.Introduction

Graphite electrodes are mainly used in electric arc furnace. They are presently the only products available that have the high levels of electrical conductivity and the capability of sustaining the extremely high levels of heat generated in EAF. Graphite electrodes are also used to refine steel in ladle furnaces and in other smelting processes. Graphite electrodes are divided into 4 Types: RP Graphite electrodes, HP Graphite electrodes, SHP Graphite electrodes, UHP Graphite electrodes.

2.Applications

Steel Production in Electric Arc Furnaces (EAF):

- Graphite electrodes are the primary conductive material in EAF, where they transfer electrical energy to melt scrap steel and other raw materials.

- They can withstand extremely high temperatures (above 3,000°C) and have excellent thermal conductivity, making them ideal for efficient steel production.

Ladle Furnace (LF) Refining:

- Used in secondary steel refining processes to adjust the composition and improve the quality of steel.

- Helps in removing impurities and controlling the temperature of molten steel before casting.

Silicon and Phosphorus Production:

- Graphite electrodes are used in submerged arc furnaces (SAF) for producing industrial silicon, calcium carbide, and yellow phosphorus.

- The high-temperature environment of SAF requires electrodes with superior thermal resistance and conductivity.

Other Metallurgical and Chemical Applications:

- Used in ferroalloy production, including the manufacture of ferrosilicon, ferromanganese, and other alloys.

- Employed in certain chemical processes, such as electrolytic aluminum production.

3.Specifications

Diameter and length for all grades:

Diameter mm | Length mm | |||||

Nominal Diameter | Actual Diameter | Nominal Length | Allowance | |||

mm | inch | Max | Min | mm | Standard | Short |

200 | 8 | 205 | 200 | 1800 | ± 100 | -275 |

250 | 10 | 256 | 251 | 1800 | ||

300 | 12 | 307 | 302 | 1800/2000 | ||

350 | 14 | 357 | 352 | 1800/2000 | ||

400 | 16 | 409 | 403 | 1800/2000 | ||

450 | 18 | 460 | 454 | 2100/2400 | ||

500 | 20 | 511 | 505 | 2100/2400 | ||

550 | 22 | 562 | 556 | 2100/2400 | ||

600 | 24 | 613 | 607 | 2400/2700 | ||

650 | 26 | 663 | 657 | 2400/2700 | ||

700 | 28 | 714 | 708 | 2500/2700 | ||

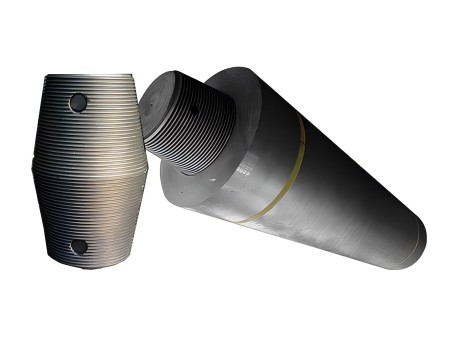

Machining Dimension of Electrode and Nipple

| Applicable | Dia. mm | IEC code | Nipple | Socket | ||

Large Dia. mm | Length mm | Small Dia. mm | Socket Depth mm | |||

UHP SHP HP RP | 250 | 155T3N | 155.57 | 220.00 | 147.14 | 116.00 |

| 300 | 177T3N | 177.16 | 270.90 | 168.73 | 141.50 | |

| 350 | 215T3N | 215.90 | 304.80 | 207.47 | 158.40 | |

| 400 | 215T3N | 215.90 | 304.80 | 207.47 | 158.40 | |

| 400 | 241T3N | 241.30 | 338.70 | 232.87 | 175.30 | |

| 450 | 241T3N | 241.30 | 338.70 | 232.87 | 175.30 | |

| 450 | 273T3N | 273.05 | 355.60 | 264.62 | 183.80 | |

| 500 | 273T3N | 273.05 | 355.60 | 264.62 | 183.80 | |

| 500 | 298T3N | 298.45 | 372.60 | 290.02 | 192.20 | |

| 550 | 298T3N | 298.45 | 372.60 | 290.02 | 192.20 | |

UHP SHP HP RP | 200 | 122T4N | 122.24 | 177.80 | 115.92 | 94.90 |

| 250 | 152T4N | 152.40 | 190.50 | 146.08 | 101.30 | |

| 300 | 177T4N | 177.80 | 215.90 | 171.48 | 114.00 | |

| 350 | 203T4N | 203.20 | 254.00 | 196.88 | 133.00 | |

| 400 | 222T4N | 222.25 | 304.80 | 215.93 | 158.40 | |

| 400 | 222T4L | 222.25 | 355.60 | 215.93 | 183.80 | |

| 450 | 241T4N | 241.30 | 304.80 | 234.98 | 158.40 | |

| 450 | 241T4L | 241.30 | 355.60 | 234.98 | 183.80 | |

| 500 | 269T4N | 269.88 | 355.60 | 263.56 | 183.80 | |

| 500 | 269T4L | 269.88 | 457.20 | 263.56 | 234.60 | |

| 550 | 298T4N | 298.45 | 355.60 | 292.13 | 183.80 | |

| 550 | 298T4L | 298.45 | 457.20 | 292.13 | 234.60 | |

| 600 | 317T4N | 317.50 | 355.60 | 311.18 | 183.80 | |

| 600 | 317T4L | 317.50 | 457.20 | 311.18 | 234.60 | |

| 650 | 355T4N | 355.60 | 457.20 | 349.28 | 234.60 | |

| 650 | 355T4L | 355.60 | 558.8 | 349.28 | 285.40 | |

| 700 | 374T4N | 374.65 | 457.20 | 368.33 | 234.60 | |

| 700 | 374T4L | 374.65 | 558.80 | 368.33 | 285.40 | |