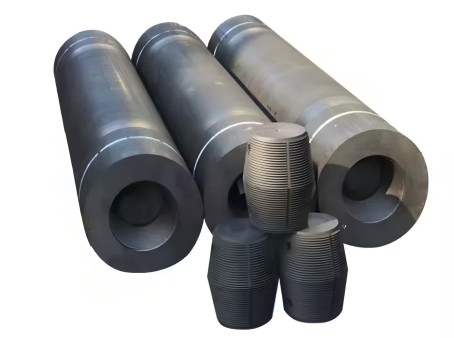

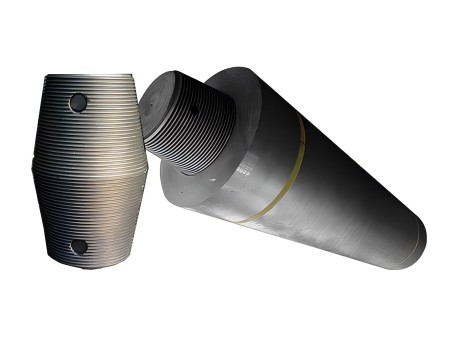

SHP Graphite Electrode

SHP graphite electrodes have excellent electrical conductivity and high temperature resistance and can protect mechanical strength. In steel or non-ferrous metal smelting, they support high temperature and high power operation.

Product Details

1.Introduction

The SHP graphite electrode, or “Super High Power Graphite Electrode,” is comprised of a particular form of graphite material that is specifically intended to tolerate extremely high currents and temperatures. “SHP” stands for “super high power,” which means it can operate steadily under extremely high-power currents. At the same time, it maintains outstanding conductivity, heat resistance, and mechanical strength. Because SHP electrodes are more resilient than regular graphite electrodes, high-temperature smelting processes may be carried out in purging and electric arc furnaces.

In brief, if a graphite electrode is deemed as an “electrical bridge,” then an SHP graphite electrode is like a “high-speed bridge”. It carries large currents to provide a stable power pathway for smelting equipment and also support the high temperatures needed for the smelting process.

2.Applications

The SHP graphite electrode is well-suited for most high-power demand applications, achieving an effective balance between performance and cost. It is an wonderful choice for high-power industrial applications. Owing to SHP’s smooth conductivity and thermal shock resistance, it excels in demanding environments. It is very durable and saves money over the long run.

SHP electrodes are more affordable than ultra-high power(UHP). It offers similar performance in many applications to provide greater economic value to users.

With high conductivity and high-temperature resistance, SHP electrode is able to accelerate the smelting process, ans that reduces time as well as saves energy consumption significantly. As a result, it improves the overall production efficiency.

SHP graphite electrodes are desirable for steeling production and smelting non-ferrous metals, as they meet the needs of diverse industries with various uses.

3.Specifications

Items | Classification | Unit | Nominal Diameter (mm) | |

300-400 | 450-600 | |||

Resistivity | Electrode | μΩm ≤ | 6.5 | 6.5 |

Nipple | 5.5 | 5.5 | ||

Bending Strength | Electrode | Mpa ≥ | 10.0 | 10.0 |

Nipple | 18.0 | 18.0 | ||

Young’s Modulus | Electrode | Gpa ≤ | 14.0 | 14.0 |

Nipple | 18.0 | 18.0 | ||

Bulk Density | Electrode | g/cm3 ≥ | 1.64 | 1.63 |

Nipple | 1.72 | 1.72 | ||

CTE(100℃-600℃) | Electrode | ×10-6/℃ ≤ | 2.2 | 2.2 |

Nipple | 1.6 | 1.6 | ||

Ash Content | Electrode | % ≤ | 0.3 | 0.3 |

Nipple | ||||

Note: Ash Content is only for reference.

Recommended current load of SHP Graphite Electrodes

Grade | Nominal Dia. | Allowable current A | Current density A/cm2 |

SHP electrode | 300mm | 14000~20000 | 19~28 |

350mm | 18000~26000 | 18~27 | |

400mm | 23000~33000 | 18~26 | |

450mm | 27000~42000 | 17~26 | |

500mm | 34000~52000 | 17~26 | |

550mm | 40000~60000 | 16~24 | |

600mm | 45000~70000 | 16~24 |